Original Factory Membrane Process In Water Treatment - UF Membrane Module PVC Ultrafiltration Membrane Module UFc80C Stainless Steel Housing Rain Water Treatment – Bangmo

Original Factory Membrane Process In Water Treatment - UF Membrane Module PVC Ultrafiltration Membrane Module UFc80C Stainless Steel Housing Rain Water Treatment – Bangmo Detail:

Applications

●Production of mineral water, mountain spring water and other germ-free liquid.

●Drinking treatment of tap water, surface water, well water and river water.

●Pre-treatment of RO device.

●Treatment, recycle and reuse of industrial wastewater.

Filtration Performance

According to the service conditions of modified PVC hollow fiber ultrafiltration membrane which are applied to various water sources, the product is proved to reach below filtration effects:

| Water Composition | Filtering Effect |

| Suspended Substances, Particles >1um | Removal Rate ≥99% |

| SDI | ≤ 3 |

| Virus, Bacteria | >4 log |

| Turbidity | <0.1NTU |

| TOC | Removal Rate 0-25% |

Above data is obtained when turbidity of feed water is less than 15NTU. The product is proved to reach the sanitary standards of drinking water by Health Department of Guangdong Province. Approval number is YUE WEI SHUI ZI 2014 S1671.

Product Parameters

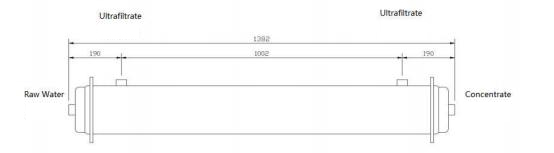

Product Appearance

Figure 1 Product Dimensions

Technical Parameters

| Structure | Inside-out |

| Membrane Material | Modified PVC |

| MWCO | 100K Dalton |

| Nominal Membrane Area | 16.5m2 |

| Membrane ID/OD | 1.0mm/1.8mm |

| Module Dimensions | Φ180mm×1382mm |

| Connector Dimensions | DN25 Female Thread |

Application Data

| Pure Water Flux | 7,000L/H (0.15MPa, 25ºC) |

| Designed Flux | 35-100L/H (0.15MPa, 25ºC) |

| Operating Pressure | ≤0.2MPa |

| Maximum Trans Membrane Pressure | 0.2MPa |

| Maximum Operating Temperature | 45ºC |

| Operating PH Range | 4-10 |

| Washing PH Range | 2-12 |

| Operating Mode | Cross-flow/Dead-end Filtration |

Feed Water Requirements

A security filter, precision <50 micron, should be set as pretreatment of UF, in case of blockage caused by large particles in raw water. Attention: UF membrane material is macromolecular organic plastics, raw water must not contain any organic solvents.

| Feed Water Turbidity | ≤15NTU |

| Oil & Grease | ≤2mg/L |

| Feed Water SS | ≤20mg/L |

| Total Iron | ≤1mg/L |

| Continuous Feeding Residual Chlorine | ≤5ppm |

| COD | Suggested ≤500mg/L |

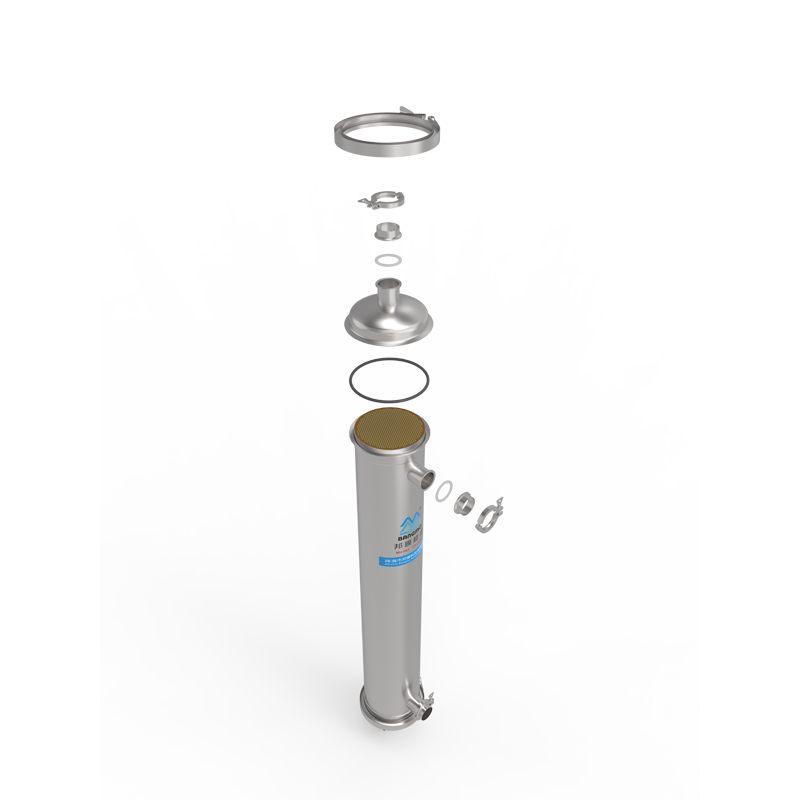

Component Material

| Component | Material |

| Hollow Fiber Membrane | Modified PVC |

| Potting Material | Epoxy Resins |

| Membrane Housing | SUS304 |

Typical Operating Parameters

| Maximum Backwashing Pressure | 0.2MPa | |

| Backwashing Flow Rate | 100-150L/m2 .h | |

| Backwashing Frequency | Every 30-60 minutes | |

| Backwashing Duration | 30-60 seconds | |

| CEB Frequency | 0-4 times/day | |

| CEB Duration | 5-10 minutes | |

| CIP Frequency | 1-3 months | |

| General Washing Chemicals : | ||

| Disinfection | 15ppm NaClO | |

| Organic Contamination Washing | 0.2% NaClo+0.1% NaOH | |

| Inorganic Contamination Washing | 1-2% Citric Acid /0.2% HCl | |

Product detail pictures:

Related Product Guide:

Our business sticks for the basic principle of Quality could be the life with the firm, and track record will be the soul of it for Original Factory Membrane Process In Water Treatment - UF Membrane Module PVC Ultrafiltration Membrane Module UFc80C Stainless Steel Housing Rain Water Treatment – Bangmo , The product will supply to all over the world, such as: Romania, Canberra, Hungary, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good solutions quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.