Best-Selling Mbr Process - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo

Best-Selling Mbr Process - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo Detail:

Product Overview

MBR is a combination of membrane technology and bio-chemical reaction in water treatment. MBR filter the sewage in bio-chemical tank with membrane so that sludge and water are separated. On one hand, membrane rejects microorganisms in the tank, which greatly increase the concentration of activated sludge to a high level, thus the bio-chemical reaction of sewage degradation processes more rapidly and thoroughly. On the other hand, water output is clear and of high quality because of high precision of membrane.

This product adopts reinforced modified PVDF material, which will not peel or break when backwashing, meanwhile has good permeable rate, mechanical performance, chemical resistance and pollution resistance. ID & OD of reinforced hollow fiber membrane are 1.0mm and 2.2mm respectively, filtration precision is 0.1 micron. Filtration mode is outside-in, that is raw water, driven by differential pressure, permeates into the hollow fibers, while bacteria, colloids, suspended solids and microorganisms etc. are rejected in the membrane tank.

Applications

●Treatment, recycle and reuse of industrial waste water.

●Treatment of refuse leachate.

●Upgrade and reuse of municipal sewage.

Filtration Performance

| No. | Item | Water Output Index |

| 1 | TSS | ≤1mg/L |

| 2 | Turbidity | ≤ 1 |

Specifications

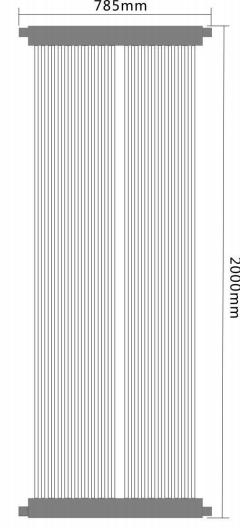

Size

Technical Parameters

| Structure | Outside-in |

| Membrane Material | Reinforced Modified PVDF |

| Precision | 0.1 micron |

| Membrane Area | 25m2 |

| Membrane ID/OD | 1.0mm/ 2.2mm |

| Size | 785mm×2000mm×40mm |

| Joint Size | DN32 |

Component Material

| Component | Material |

| Hollow Fiber Membrane | Reinforced Modified PVDF |

| Sealing Compound | Epoxy Resins + Polyurethane (PU) |

| Housing | ABS |

Application Parameters

| Designed Flux | 10~25L/m2.h |

| Backwashing Flux | 30~60L/m2.h |

| Operating Temperature | 5~45°C |

| Maximum Operating Pressure | -50KPa |

| Suggested Operating Pressure | 0~-35KPa |

| Maximum backwashingPressure | 100KPa |

| Operating Mode | 9min Operation+1min Break/8min Operaetion+2min Break |

| Blowing Mode | Continuous Aeration |

| Aeration Rate | 4m3/h.pc |

| Washing Period | Clean water backwashing every 2~4h; CEB every 2~4 weeks; CIP every 6~12 months |

Using Conditions

There should be appropriate pretreatments before UF. If defoamer has to be used, please choose alcohol defoamer, silicone defoamer is forbidden.

| Item | Value |

| PH Range | 5~9 (washing: 2~12) |

| Particle Size | <2mm, no sharp particles |

| Oil & Grease | ≤2mg/L |

| Hardness | ≤150mg/L |

Product detail pictures:

Related Product Guide:

So as to provide you with ease and enlarge our business, we even have inspectors in QC Crew and guarantee you our company and solution for Best-Selling Mbr Process - MBR Membrane Module Reinforced PVDF BM-SLMBR-25 Waste Water Treatment – Bangmo , The product will supply to all over the world, such as: Hyderabad, Morocco, Cancun, Our items have national accreditation requirements for qualified, high quality products, affordable value, was welcomed by people today all over the world. Our goods will continue to enhance within the order and look forward to cooperation with you, Should any of these products be of interest to you, please letus know. We are going to be content to offer you a quotation up on receipt of your detailed needs.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!